Here is a link to more information about the energy crisis in the 1970's:

Wiki page on oil crisis

Amusing take on why they did not insulate

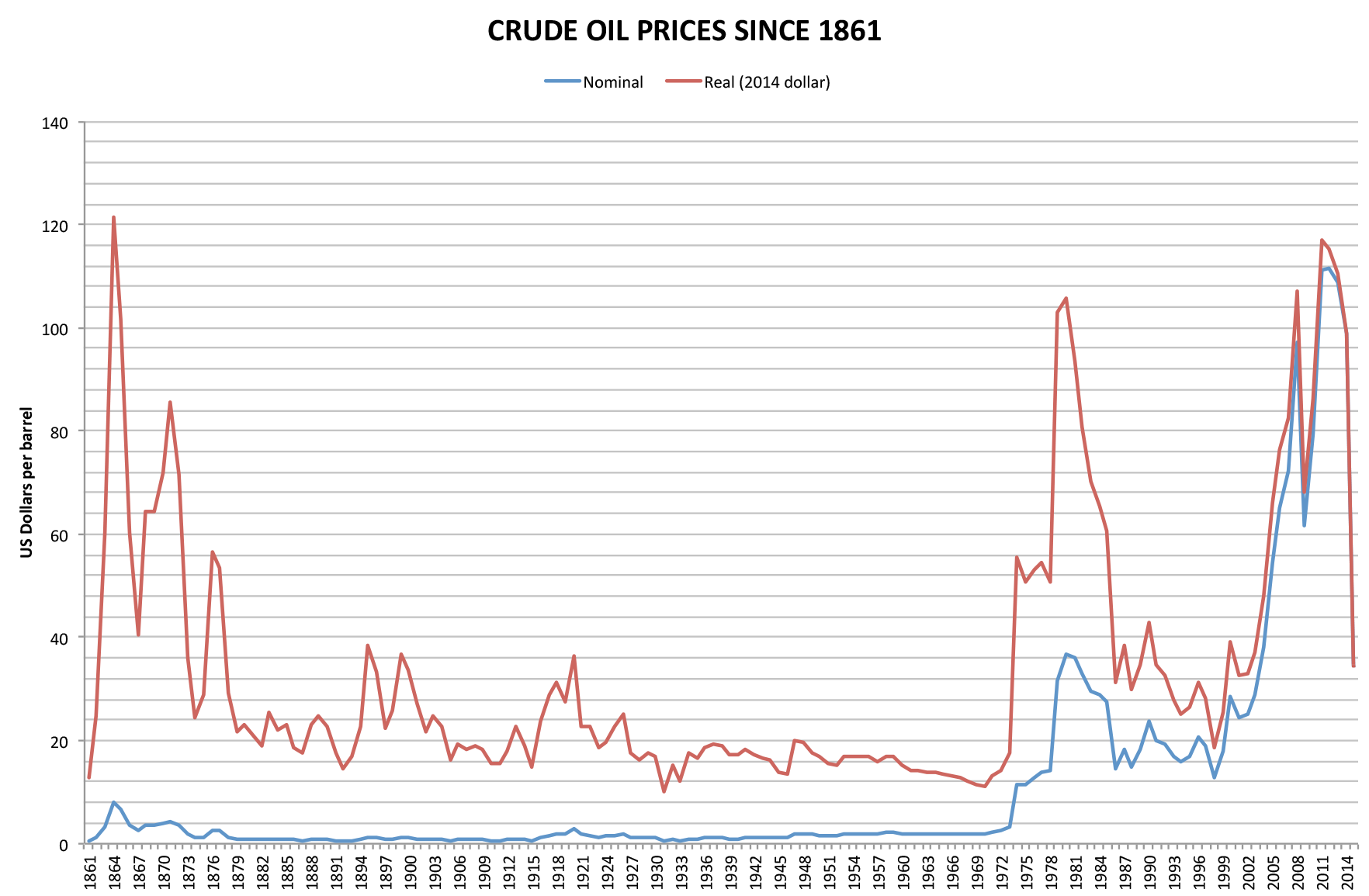

From the wiki link you can see this chart of oil prices:

Notice the spike in 1973 and 1979.

Link to historical oil prices:

Oil Price History Chart

The whole first floor of our house has an outer wall of stone. Between the stone and the cement board (old-time sheet rock) that makes up the inner walls of our first floor, is air. No insulation!

I want you to imagine sitting in your house on a blustery cold winter day. A strong wind pounds against your house. Not only can you hear the wind, but you can feel the air in your home move with it. That is what it feels like to not have insulation in your walls.

If you have this problem in your own home, you can pick one of two solutions. First, you can knock down every wall in your house, and put in new insulation and walls. Second, and more practical, is you find or make a cavity that connects to the empty space, and fill each space between the wooden boards with blown-in insulation. In some houses, you might have a space between the wall and ceiling in the basement that connects to the first floor. In that case, you could blow insulation into the cavities from the basement. Another option is you might have cavities that are above your walls in the floor of crawl spaces or the attic that connect to the inside of your walls. Then, you could blow in insulation from above. However, if neither options are available to you, then you will have to do what we will show here. We had to make a hole in every wall of the first floor between the beams and fill it with insulation (some people make holes in their masonry and fill cavities if they cannot reach it from the inside walls, thankfully we did not have to do that!).

Here is a website with a cartoon video of exactly what we did:

Video of Blown-in Insulation

Before Insulating:

Second we went to Home Depot and checked that they had the insulation in stock, and that there were machines available to rent. We checked the diameter of the nozzle of the machine to make sure we would drill the holes the right size (1"). They have a deal that if you buy 20 cubes of loose fill insulation they will give a free one-day rental. We also tried to approximate how much insulation we will need.

Third, the week prior we drilled the holes and moved furniture and pictures away from the outer wall of the first floor.

Here is a picture of some of the holes we made. We drilled them close to the ceiling, but not above windows, only below window sills. We intend to replace the windows eventually, so we will fill those spaces in later.

We filled about 50 cavities, and it took us half a day. Starting at about 8am, we were done by 3pm. It took a few hours to get into a groove where we did not get clogs in the tubing nozzle or hose. I will share some tips for making this process go smoothly.

Breaking Up The Insulation:

The machine came with two garbage cans that held the huge hoses. We used the cans (as other renters probably did as well) to break up the loose insulation into manageable chunks by hand. You can use a garden scraper, shovel or dust pan to roughly loosen it up. Please do this while wearing a dust mask and eye goggles. Some of our implements are pictured below:

You really do need to break up the insulation by hand if you are using the attached nozzle to blow it into a wall. If the tubing gets clogged you are likely to make a huge mess and waste a lot of time unclogging it. Below is a picture of what the insulation looks like broken up into a garbage can.

However, you do not need to go crazy breaking up the insulation perfectly by hand in the garbage cans. As we found out after working for a few hours, it is best to let the machine do most (not all) of the tilling. Below is a picture of the machine breaking up the insulation and blowing it through:

Filling Up The Machine:

There is a sliding gate on the bottom of the machine that controls how much material flows through. We found out that if you close the gate to about and inch and a half, and let the machine churn a whole bunch of the material for a few minutes, you can then open the gate really wide and let a huge stream of insulation fly through. This seemed to work better then breaking it up really well by hand or leaving it at a low flow for the whole time. Below is a picture of machine with the exit hose, the orange gate shows you that it is almost closed.

Filling The Walls:

The person who is filling the holes also can do their part to prevent clogs. If you hold the hose immediately behind the nozzle at the same level, it gives the insulation a stronger push through the nozzle. The downside is the loss of blood in your arms as you hold them above your head. See picture below:

Here is a close up shot of the nozzle pushing material into the wall:

Here is what the hole looks like when it is completely filled with material:

When you are all done you can seal the holes with an expanding foam spray, found in the same aisle with the insulation. When that dries you can shave off the excess, compound and then paint it over. See photo below:

When I sit at home now, I no longer hear the noises from the street or feel the wind blow through my house! We were left with 6 bags of insulation (cost about $10 each) which we returned, and Home Depot still let us have the free rental! The final expense for this project was ~$130 and a half days hard labor for two people. The savings in utility costs will make it very worthwhile.

Here is final picture of the mess left behind (the reality of doing any work on your house):